Static NBS Thread 99-07c

- Thread starter Samuel6731

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Was about to pull the trigger on some coilovers. Dnw to spend more $ on the truck though so I guess I'll cut springs when I raise the crossmember.

i talked to joey about a 2 piece, he used some aluminum to make a bolt in cross member. then bolted an old carrier bearing bracket to that cross member. said he was gonna try manufacturing a few, but couldnt figure out that bracket he had. seems very easy, ill definately be doing it. dnw a gernade blowing up under my truck lol.

Bam.

Quite a few people have been messaging me lately asking about how I did my 2pc, so I figured I'd make a thread on it. The big ass 1pc shaft usually becomes a problem when you lower a ccsb 4"+ in the back. There's quite a few ways to do it, but this is how I did mine..

Removed the 1 pc, and put the 2 pc to see where the new cross member needs to go and what's in the way.

The evap canister was the only thing that needed to be moved, so I started on that. This is how it sits stock

Take all of that out and make a new bracket to mount it sideways. I just used a piece of alum flatbar and bent it over the top of the frame.

Then drilled holes and bolted it to the frame

So this is how it should look now, or something close to this as long as you can mount a new cross member under it.

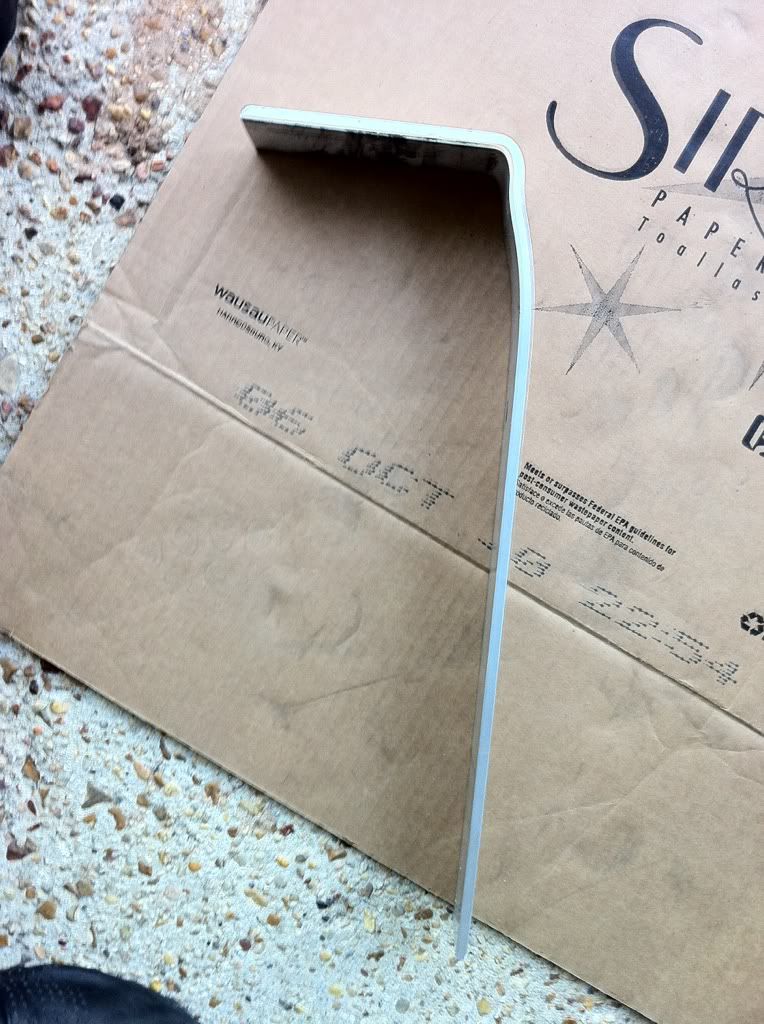

There isn't much strain on the carrier bearing at all, so I just used a piece of 3" alum C channel I had laying in the shop, and a bracket out of a carrier bearing relocation kit since it was already slotted for the carrier bearing mounting holes and would be somewhat adjustable. I cut the xmember to fit inside the frame rails on the inner lip since i couldn't weld it on.

I don't have any final installed pics but I just set the cross member inside the rails on the inner lip and put the carrier bearing in it, then used ubolts from the bottom to hold the cross member. This also makes it removable. The ubolts hang down like 1/4" which I was worried about at first but I've had them like that for probably 20k miles and even after dragging on them quite a few times they're still strong. ubolts I used, except longer:

Next time I get under my truck I'll snap some pictures of it mounted in, thought I had some but I can't find them now. Hope this helps :cheers:

why not just run a 2-piece?

Colyn is trying to trade with him iirc

Think about it...2 piece is actually superior...and ecsb has it...SO HE WOULD BE STUPID TO TRADE imo