05 CCSB slow build

- Thread starter 2005_Silverado

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

So I've been having over charging issues for a few weeks now, DC says the alt is a dummy and just does as its told since it doesn't have a voltage regulator like the 4 pin alts do. XS says their batts are probably good and to check the charging voltage. So I swapped alts and still have the same issue, its not the alts. I bought a new D3400....still have the same problem....volts will climb to 15.2v and stay there, no matter what  issed: Problem did go away when I swapped batts but its back again after a few days, which seems to be what happens after the computer relearns and whatnot. After some googling....turns out that the 2 pin alts have a lil blek box on the negative battery cable which controls the alternator output. People have reported the same issue as I had....start at 14.6v and then climbing to 15.2v and staying there :nono:

issed: Problem did go away when I swapped batts but its back again after a few days, which seems to be what happens after the computer relearns and whatnot. After some googling....turns out that the 2 pin alts have a lil blek box on the negative battery cable which controls the alternator output. People have reported the same issue as I had....start at 14.6v and then climbing to 15.2v and staying there :nono:

For anyone having this same issue and having a 2 pin alternator, swap the SARVC module. Ive got one coming my way, will post results.

For anyone having this same issue and having a 2 pin alternator, swap the SARVC module. Ive got one coming my way, will post results.

That little block is called the GBCM (generator battery control module). It's the reason I have a battery light on my cluster.

That lil box take a shit on u? Im not getting any dash lights or anything...just going straight to 80% duty

http://acdelcotechconnect.com/pdf/imtn_V12I305.pdf

http://www.gmtruckclub.com/forum/threads/battery-light-woes-and-hard-starting.135953/page-3

http://acdelcotechconnect.com/pdf/imtn_V12I305.pdf

http://www.gmtruckclub.com/forum/threads/battery-light-woes-and-hard-starting.135953/page-3

Last edited:

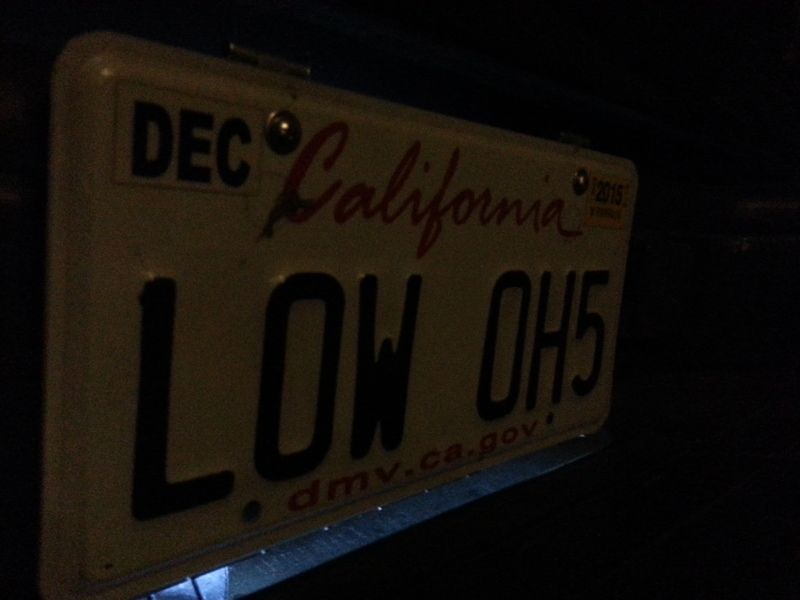

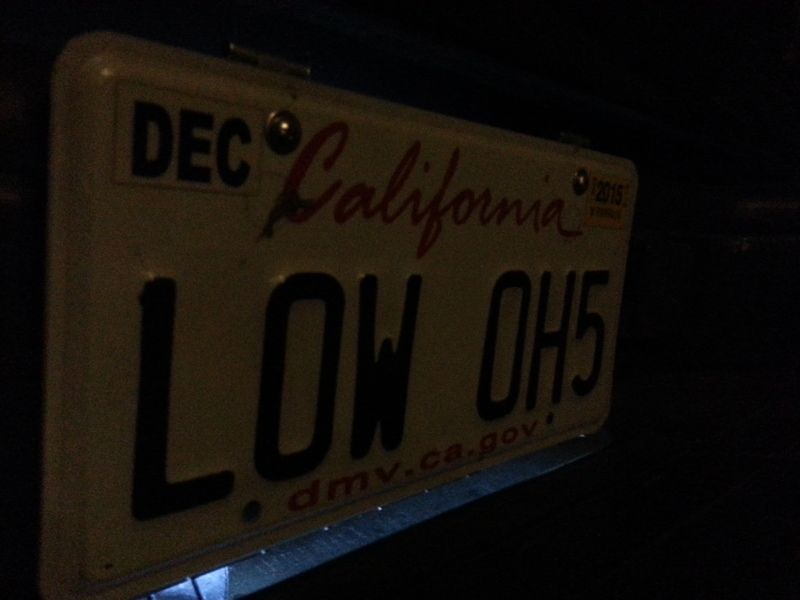

sent u mcmaster link for air chuck that wont leak :mexiokay:so ive been buying parts here n there to make me a bracket to mount my air chuck and switch. will bolt angle iron to xmemer, some square tube, then angle iron to bolt up some diamond plate. Air chuck will be activated with a switch that will open and close the air valve. Ive seen too many air chucks leak...dnw it plumbed directly to the tank, hence the e-valve. All this will be hidden behind the lic plate which will flip up with simple hinges. Plate is done, just gotta start cutting some metalepper:

pero dont leak, jew just put band aid on with air valve :datgold:mf chuck was like $50

So I been wanting to do this for a while....this is what its gonna look like until the alum gets welded

Plate on simple hinges

Flip that bish up and dis is what youll get

Put some LEDs under there that will be wired into the same switch that I'll use to open up the air valve

So if I ever need air, I can just get my air hose, flip the plate up, push a switch and hook up my line. Been wanting to do it since I visited my brother in Phx a while back....we went out to eat, came out and truck tire was low, no gas station had a working pump so I had to drive a bit on low af tire to find a working pump issed: Felt so retarded having OBA but no way to access it :roflpow: I'll post a vid once I put the valve in and finish it up.

issed: Felt so retarded having OBA but no way to access it :roflpow: I'll post a vid once I put the valve in and finish it up.

Plate on simple hinges

Flip that bish up and dis is what youll get

Put some LEDs under there that will be wired into the same switch that I'll use to open up the air valve

So if I ever need air, I can just get my air hose, flip the plate up, push a switch and hook up my line. Been wanting to do it since I visited my brother in Phx a while back....we went out to eat, came out and truck tire was low, no gas station had a working pump so I had to drive a bit on low af tire to find a working pump

I still need to invest in a good on board setup and do this. Still rocking my Harbor freight tire pump that I wired on a switch lolz. Was meant to be temporary while I was on a tight budget but I've never messed with it again. Gonna redo my whole helper setup soon though.

Sent from my SM-N900V using Tapatalk

Sent from my SM-N900V using Tapatalk

That's sweet. I know a lot of people, my self included, that have been looking into ways to add air to run tools off from the truck, and that's probably the cleanest set up I've seen.

Sent from your girls iPhone.

nice n hidden but easily accessible was my goal. I actually got the idea from billy....he has his air chuck in the lil spare tire lock hole thing on the bumper....but that seems like it would be hard to get the chuck to release....never tried it on his. lil diamond plate is plenty big to put a panel mount pressure regulator there and run air tools. My 444c fills up my 5 gal tank to 200psi, plenty of air to run an impact at 80-90 for a bit. :shake:

I still need to invest in a good on board setup and do this. Still rocking my Harbor freight tire pump that I wired on a switch lolz. Was meant to be temporary while I was on a tight budget but I've never messed with it again. Gonna redo my whole helper setup soon though.

Sent from my SM-N900V using Tapatalk

I had lil craftsman pump until someone thought they needed it more than I did and jacked it

thanks fellers :shake:

I put mine in my spare tire door. Was able to fit the hose through the opening added the fitting and it slides in and shut the door

Dropped off my stuff around 12....was ready at 2

now if the damn air ride shop woukd open I could buy the valve n fittings I need

now if the damn air ride shop woukd open I could buy the valve n fittings I need