:shake:

Couple of pointers if any u fgts decides to get them too....the bolts are HUGE fgts to get them into the threads in the heads. I used a magnet to keep the bolt straight as possible and get it started.

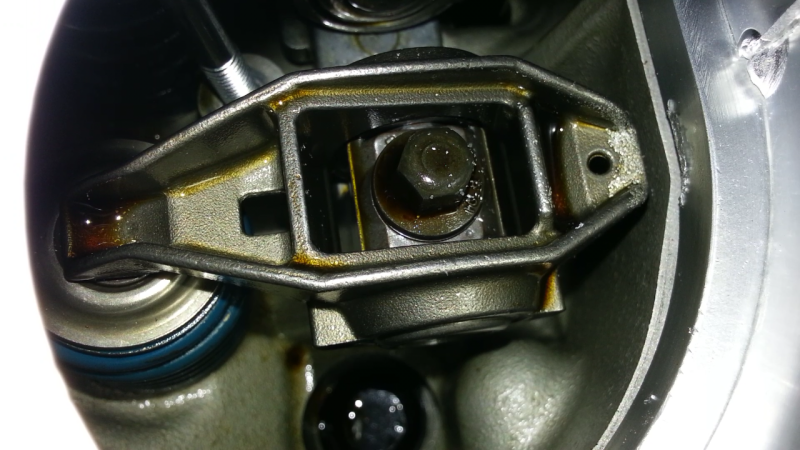

The covers don't have a lip on the inside, so they can slide off real easy...didn't seem like a big deal to me till I started the truck and noticed the pass side VC SHAKING....I killed the truck and found this

The cover was too low and the top of the rocker was hitting the inside :rofl:

ow: :fp: :nono: pulled the coil pack off that head, loosened the VC and repositioned, all good now but Id imagine it could slide back down over time. Ill have my welder put some tabs along the bottom so that doesn't happen again :nerd:

- - - - - - - - - -auto merged double post- - - - - - - - - -

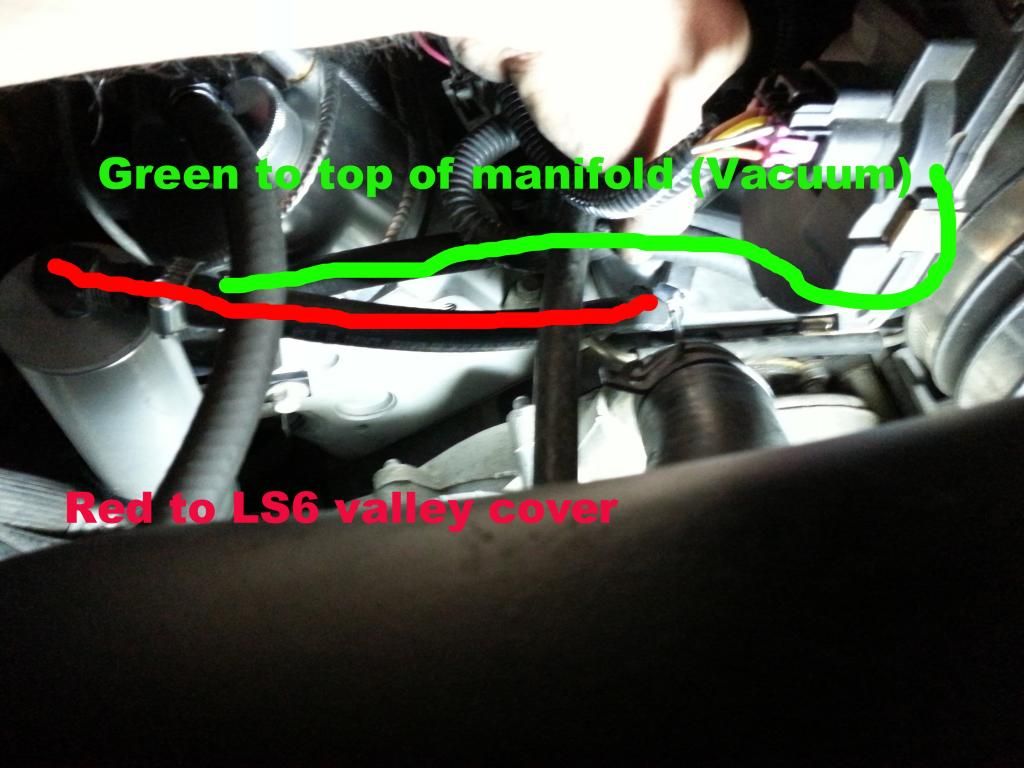

To install the catch can and keep some sort of PCV system, I installed an LS6 valley cover that has a built in PCV valve. Unlike my LM7 which has a "valve" on the driver VC, the LS6 has an actual PCV valve but its in the valley cover. This worked out perfect since the LS6 still uses knock sensors in there, unlike Gen IV motors that have external sensors. I removed the intake, pulled the sensors out, swapped covers and reinstalled sensors n harness. Plumbing the lines was EASY as fok.

The green line normally goes from top of the intake to the driver side VC directly...that's why the intake sucks in the oil and goes into the combustion chamber....fts, u want to separate the oil from that air. I don't have many miles on my 243s and they already had an oily film on them :nono: Hopefully this cures that and provides a cleaner/more efficient burn.

Up next is an external engine oil cooler, im hoping this helps reduce oil vapors as well

ray: