Busy weekend of progress.

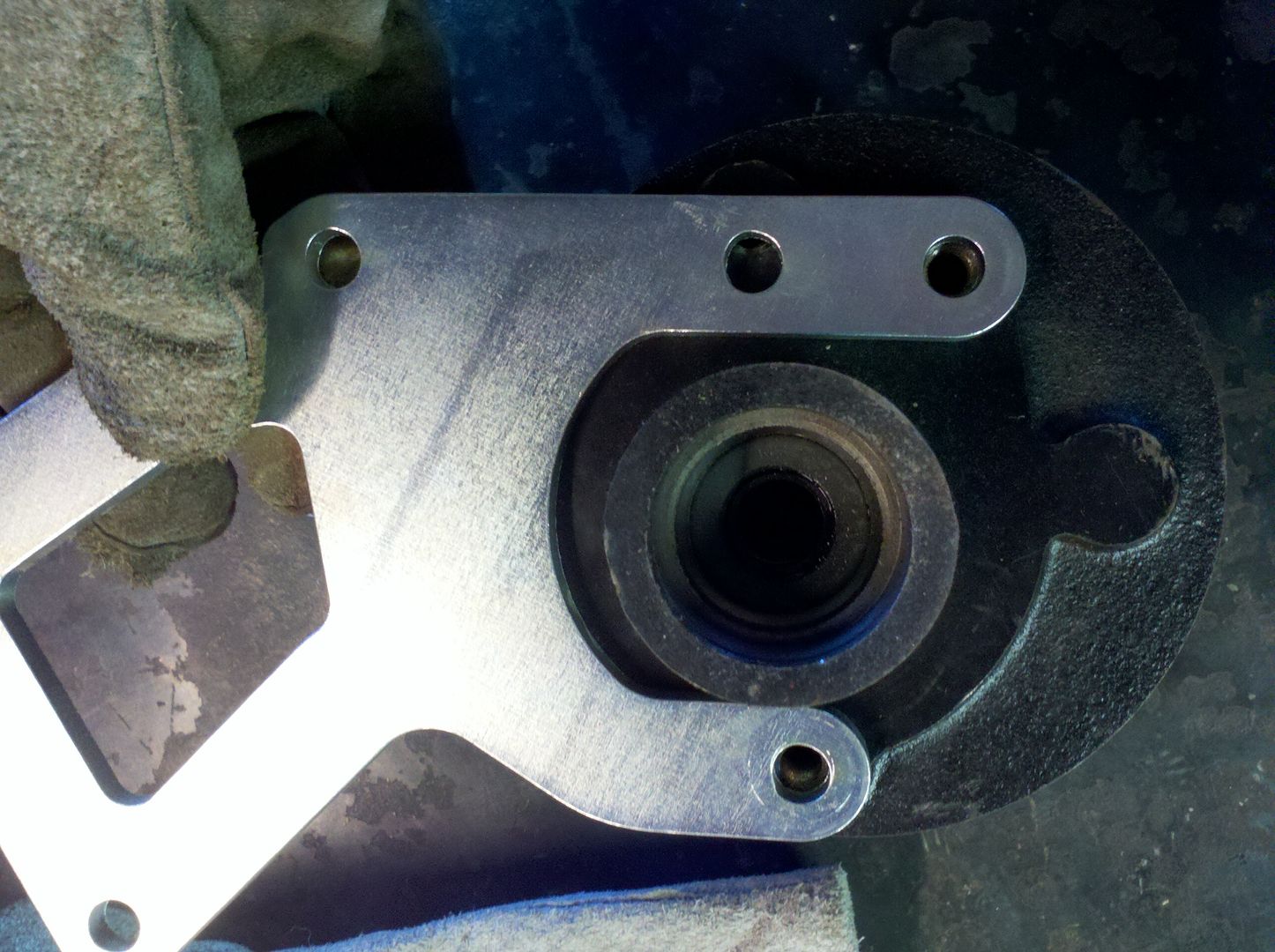

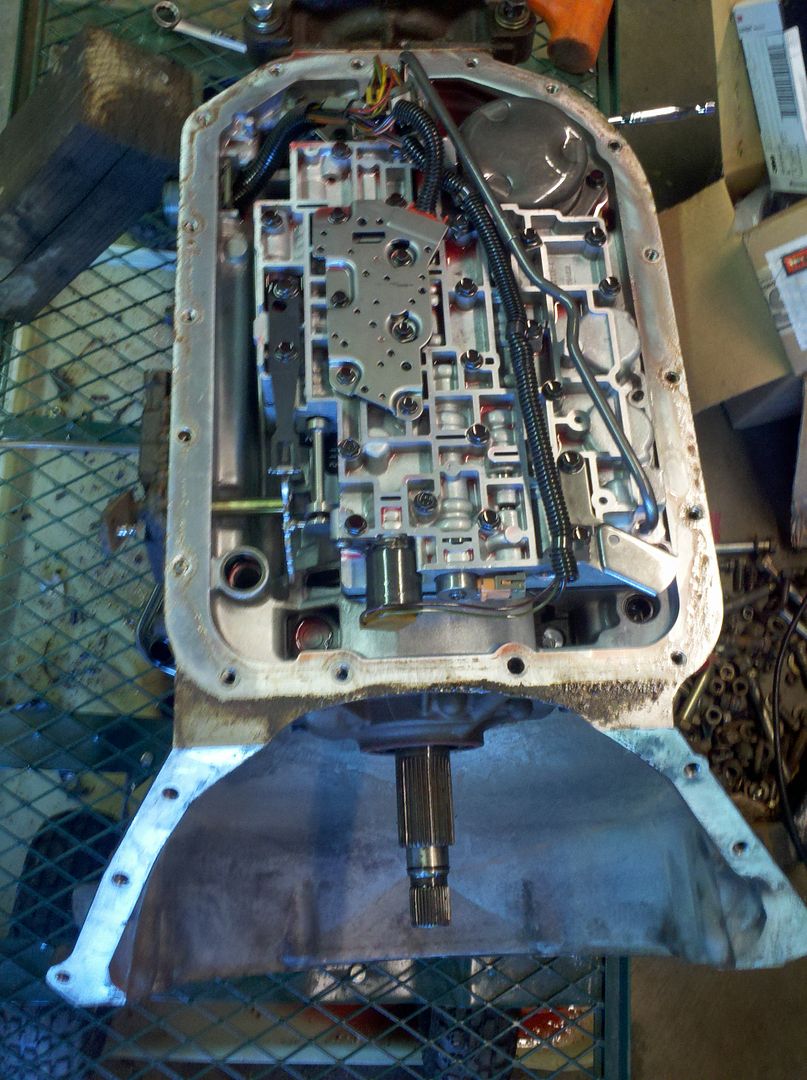

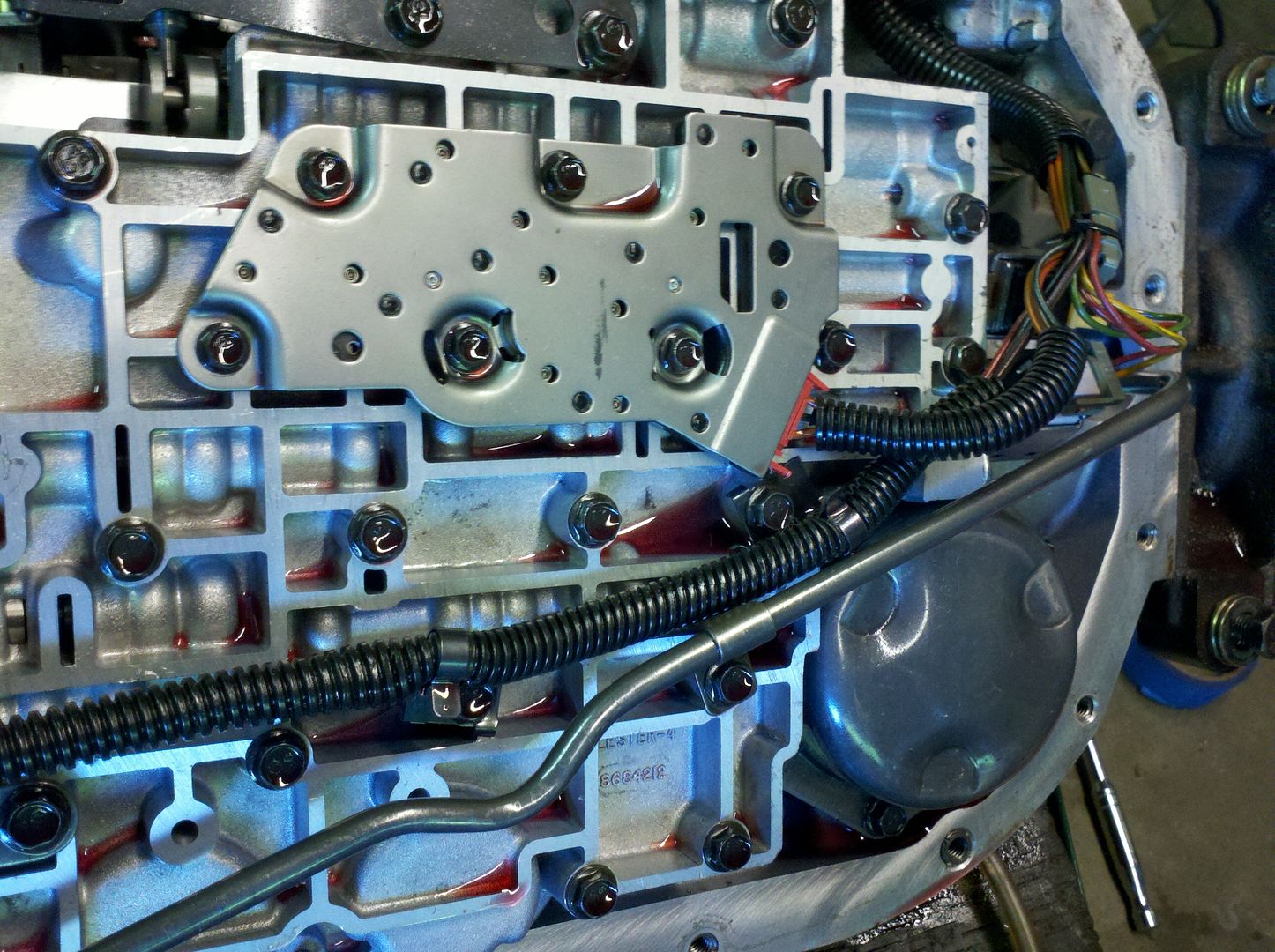

Started by pulling the tranny off to put in the replacement dowel pin, shortly followed by tossing the t-case in behind it after cleaning the wee out of the FHCS that mount the clocking ring as well as the t-case mating surface and blind tapped holes so the Locktite would bite. Two gaskets and consistent torque and it may seal this time.

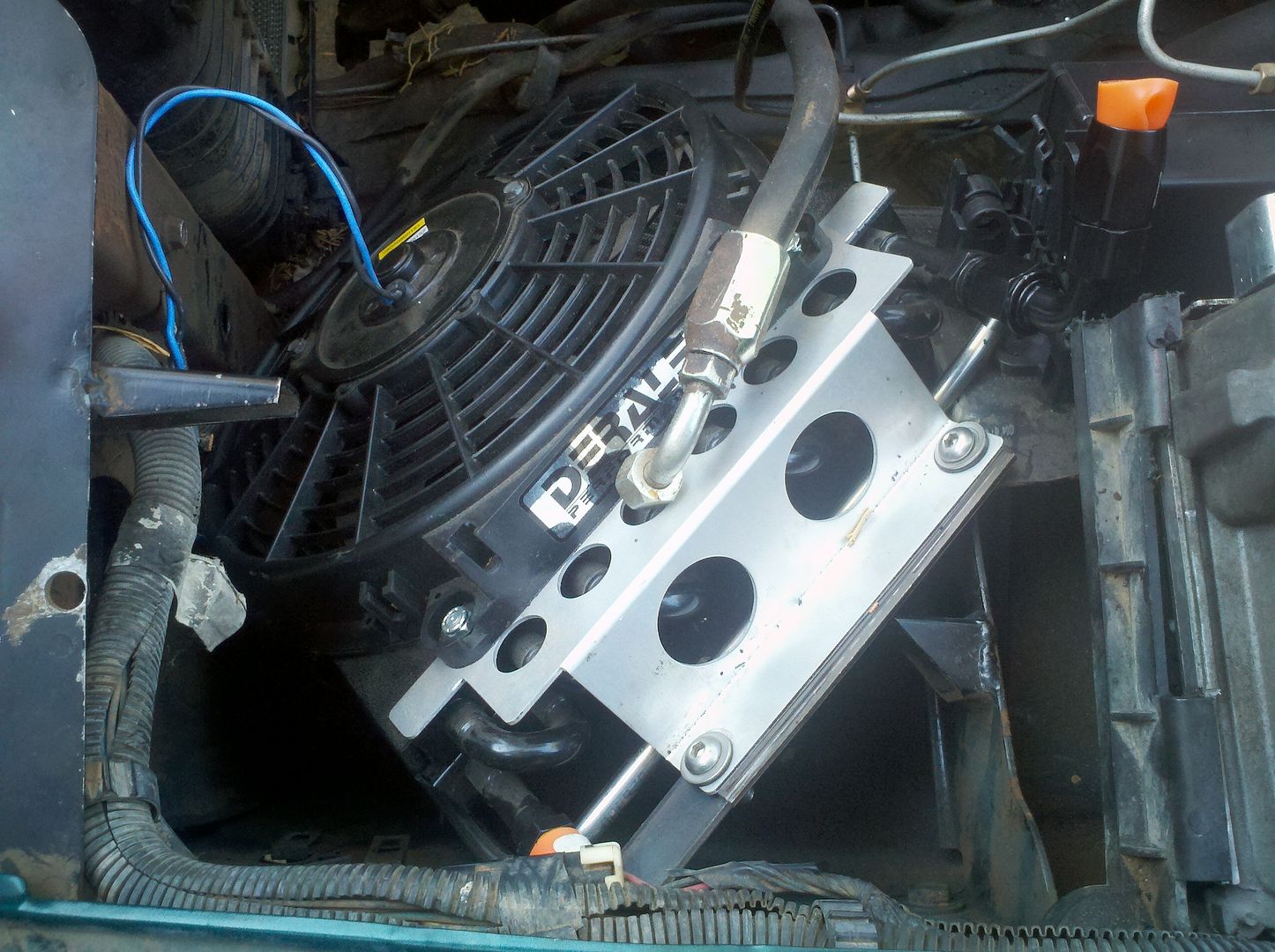

Bent some leftover tube and welded some thin plates to make a mounting frame for the cooler.

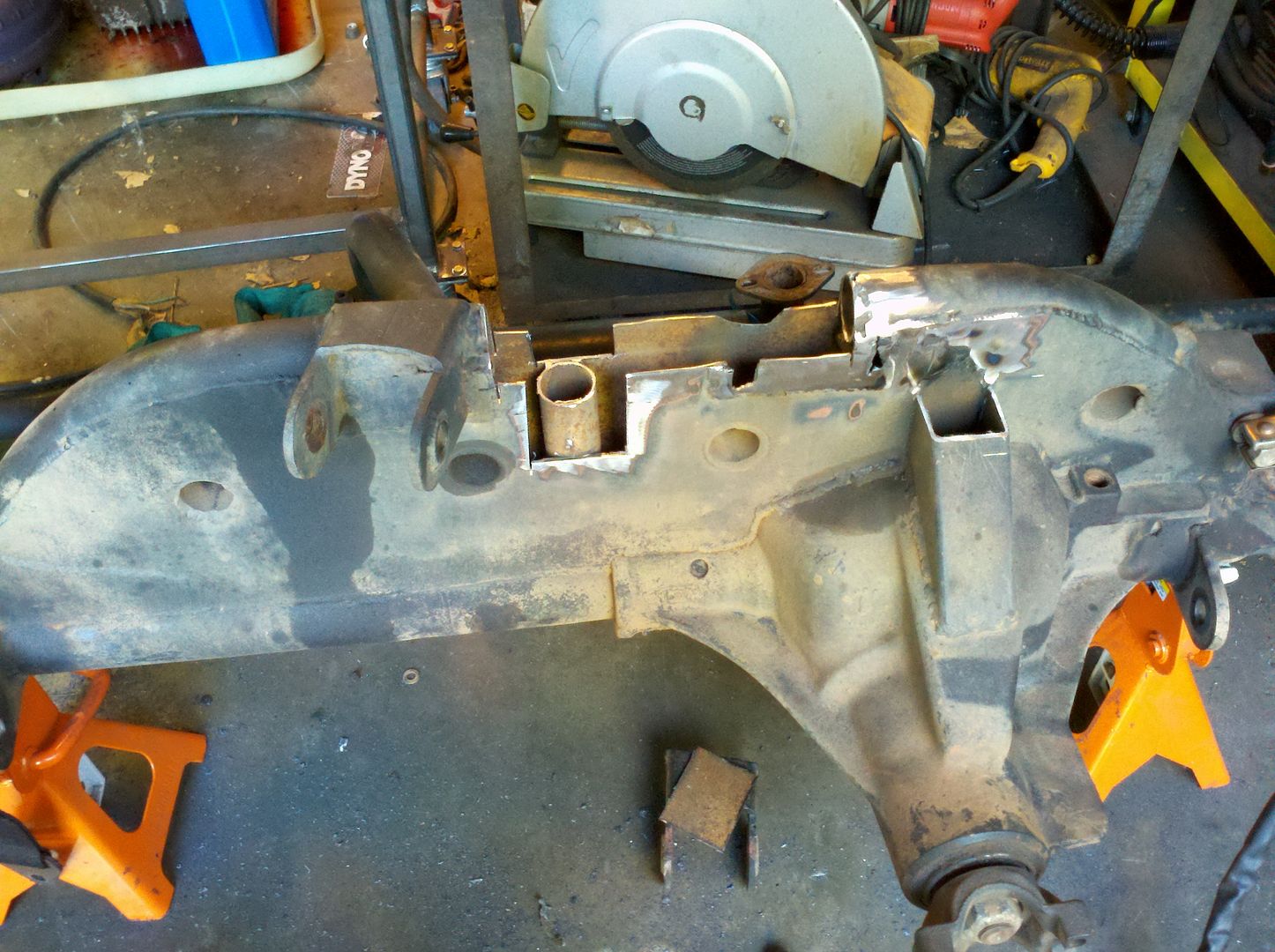

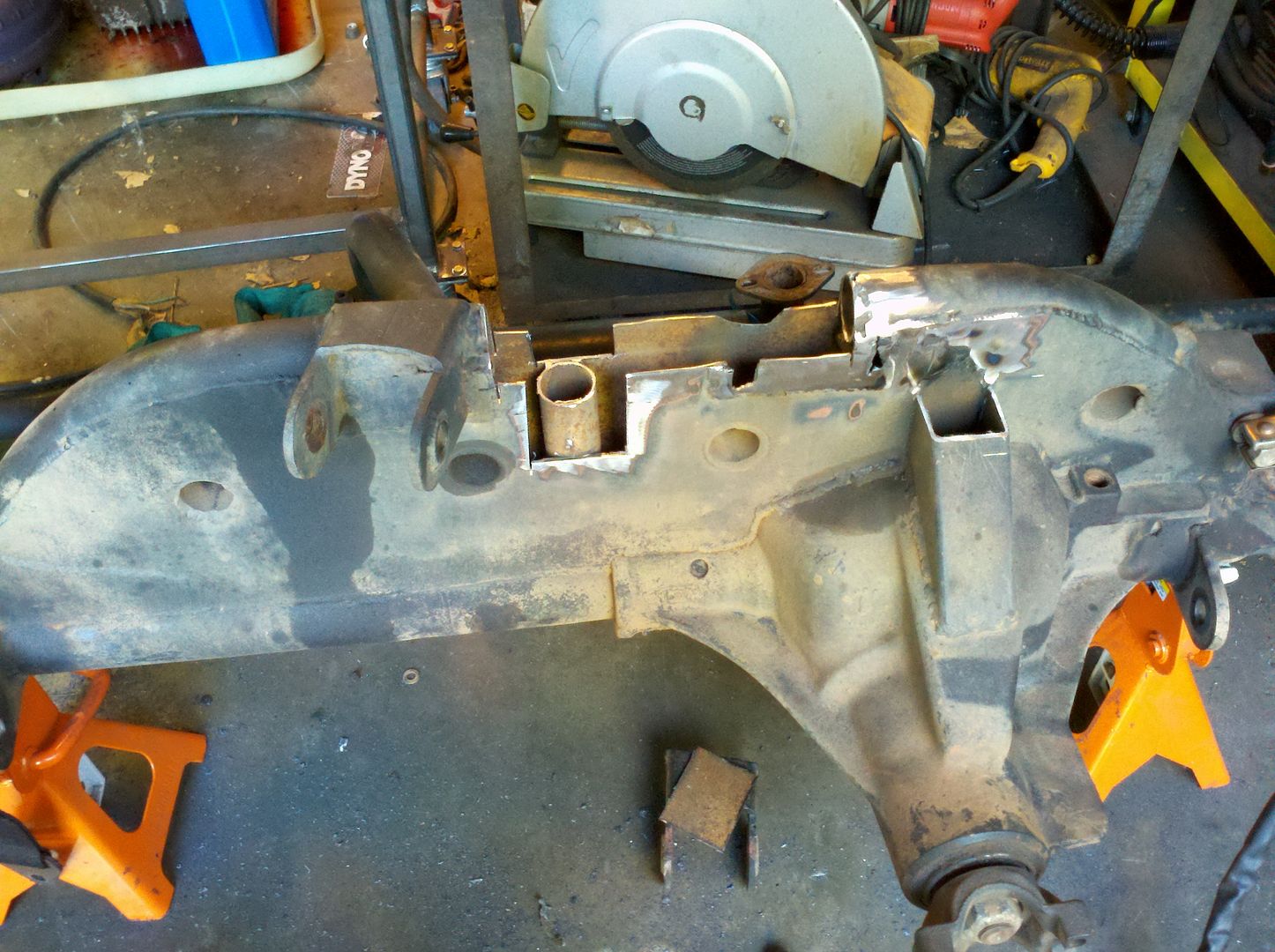

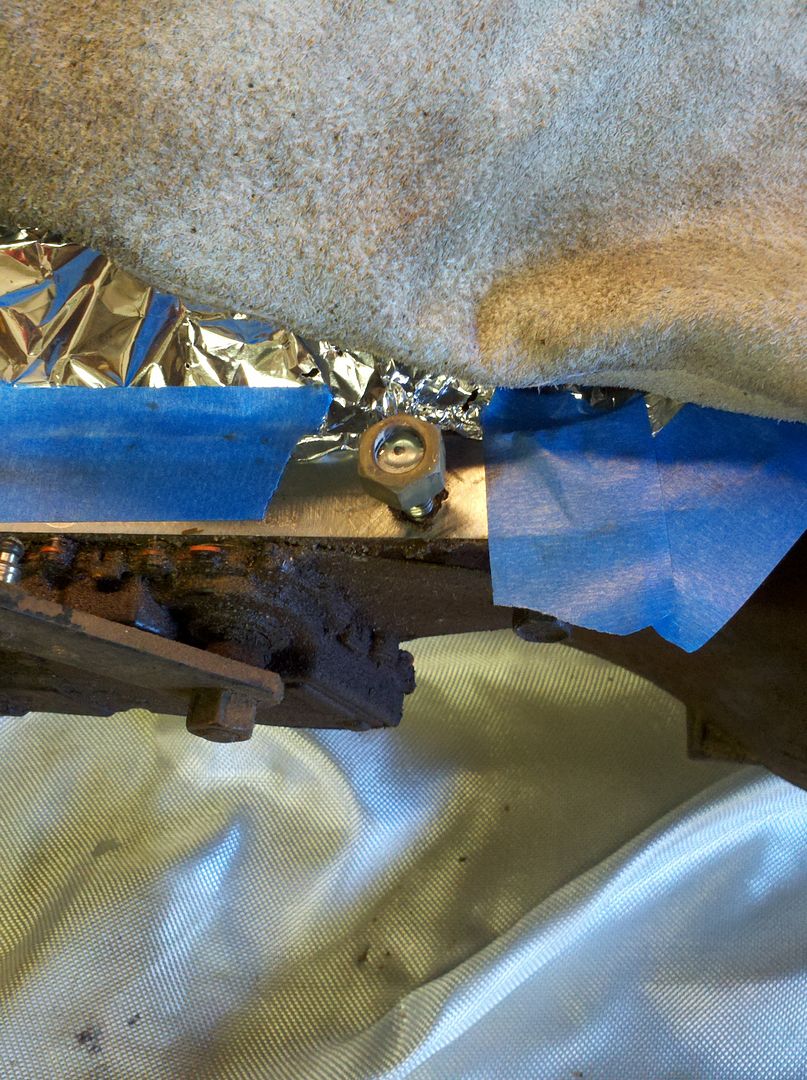

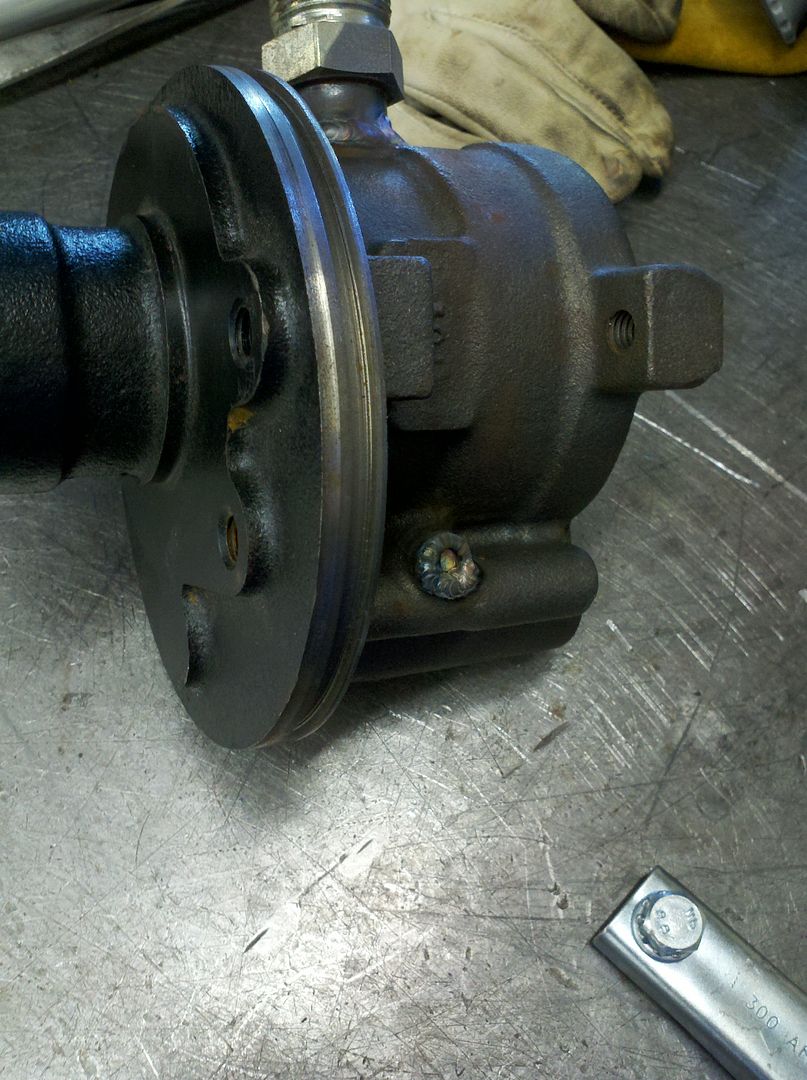

The belly crossmember had previously just been tapped to 1/2-20 through the 1/8" wall. Enough strikes on the cap screws holding the skid plate on meant a lot of stripped holes.

To fix it I needed to devise an easy way to weld some nuts in. The simplest solution I had was to grind the points on the nuts down a touch to make them 12 points basically. Then I opened the threaded holes up to 3/4" and took a chamfering tool and chamfered until the 3/4" lip was .005-.015'ish thick. I threaded the modified nuts onto a fully threaded bolt and used a hammer on the bolt to drive the nuts in. The 12 external points just broached through the chamfered edge resulting in a press fit that held them in place and I had good void to fill with weld so I didn't feel bad grinding them flat.

All done, repeat 6x.

Then I went to put the frame in...lets just say I called it a night on Saturday. Seems the adapter plates moved the drivetrain forward 1-1/2"s.

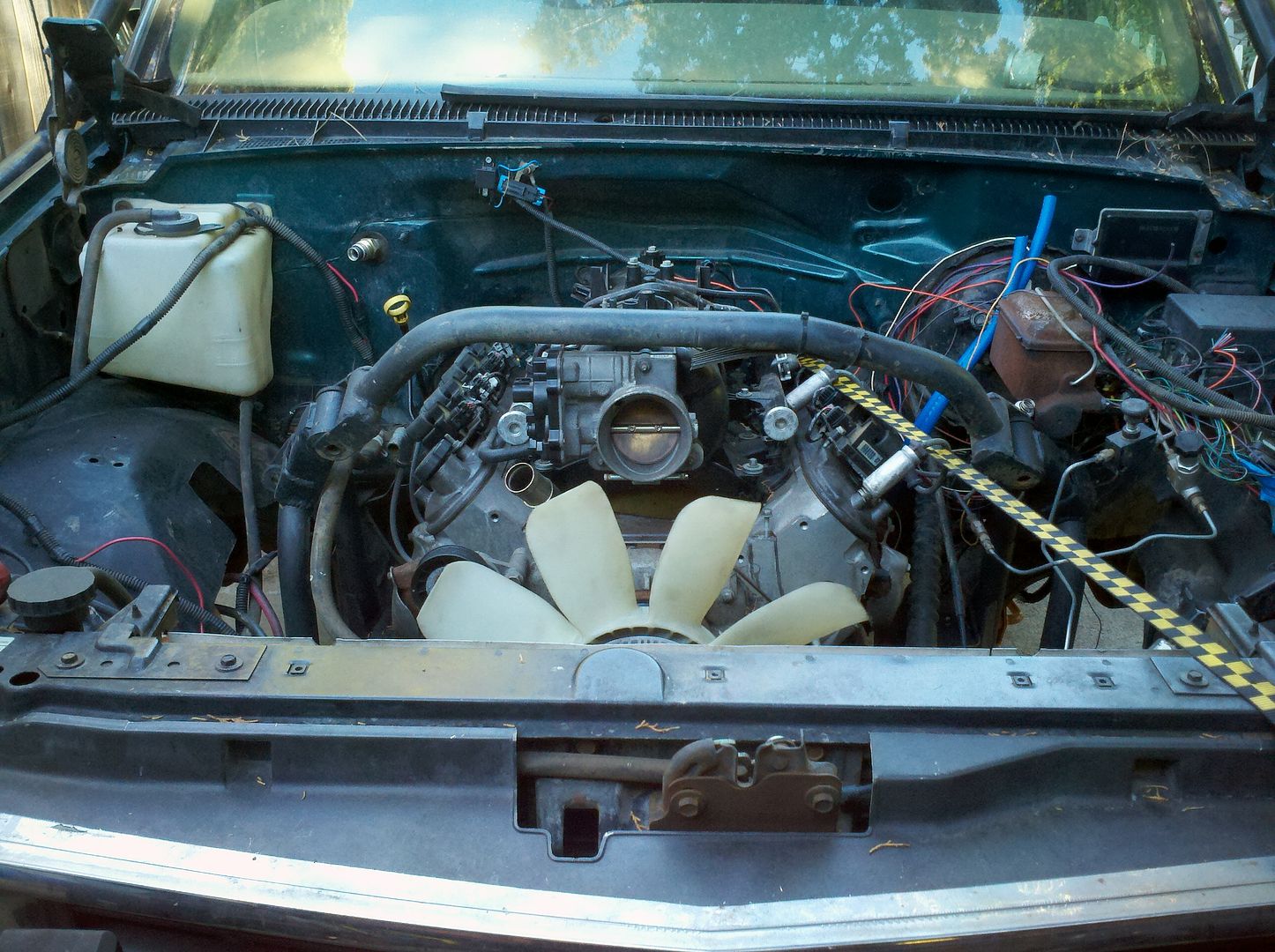

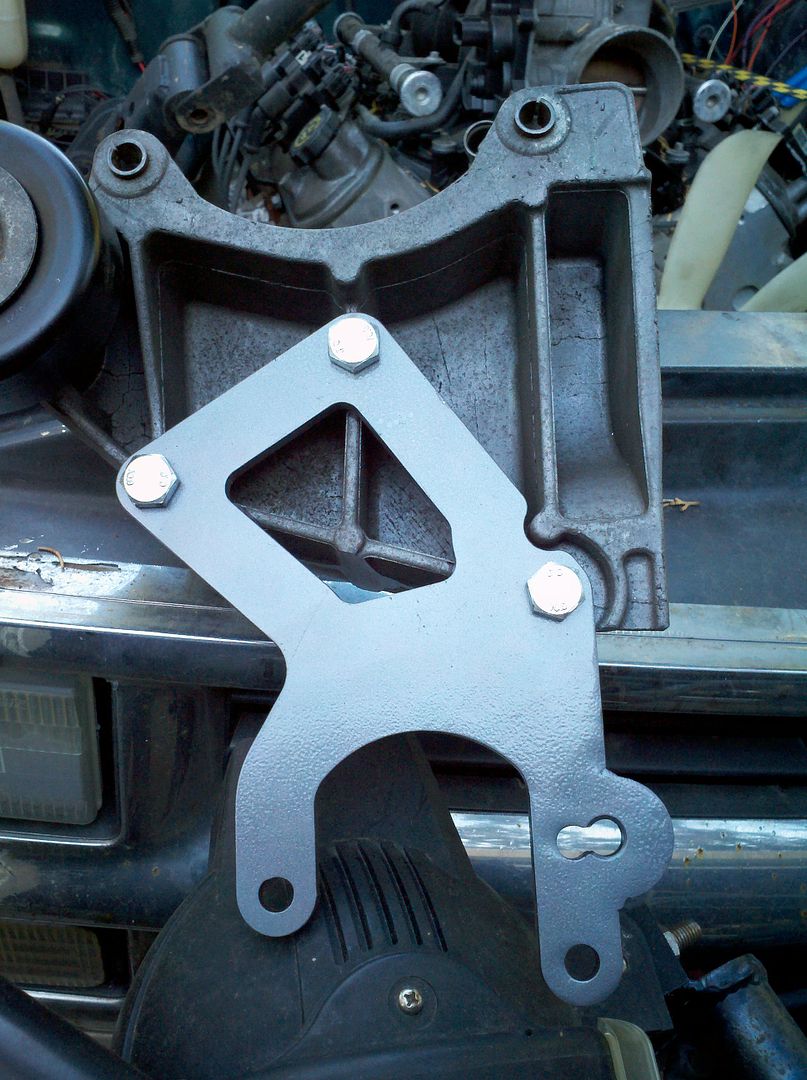

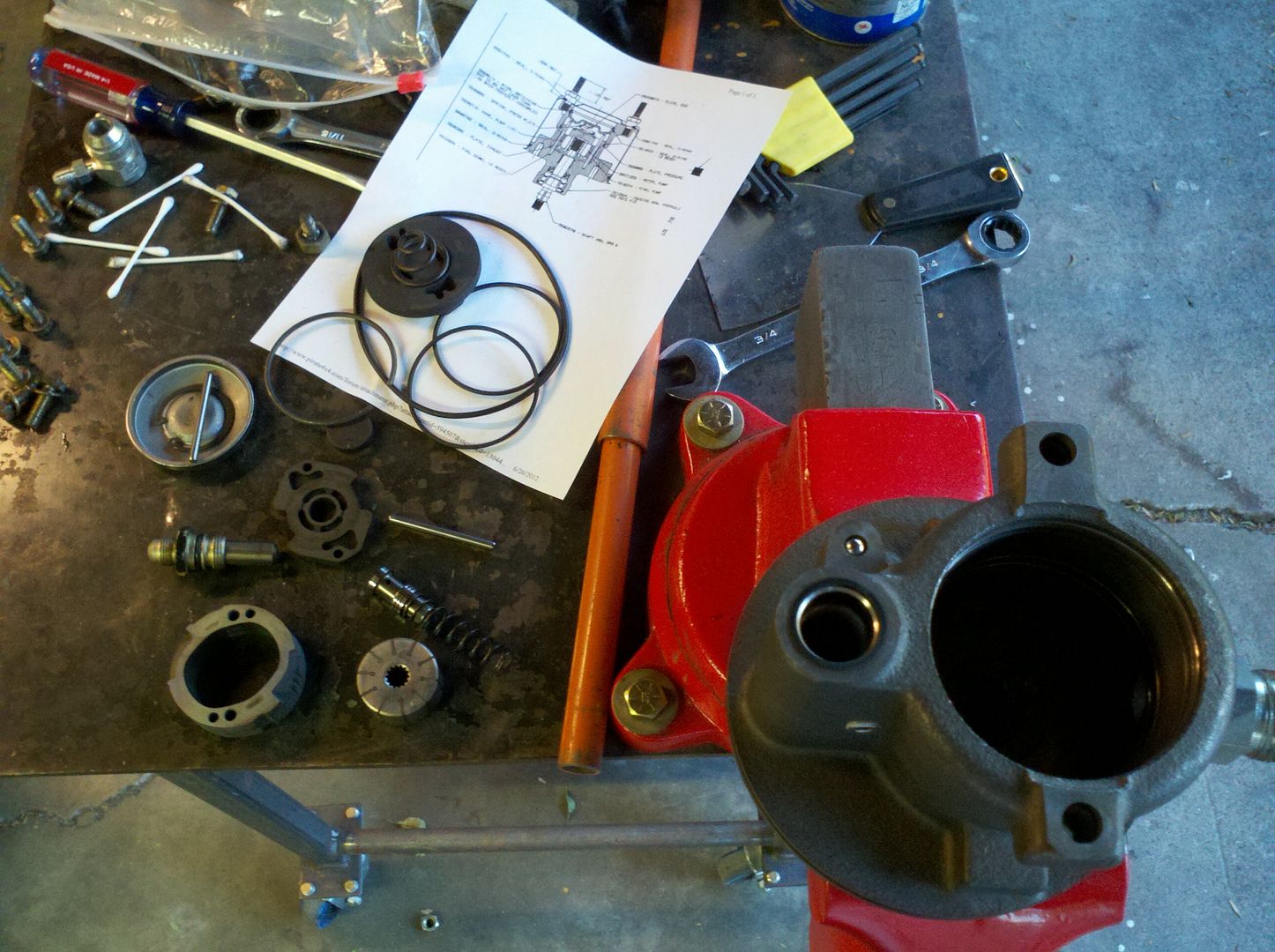

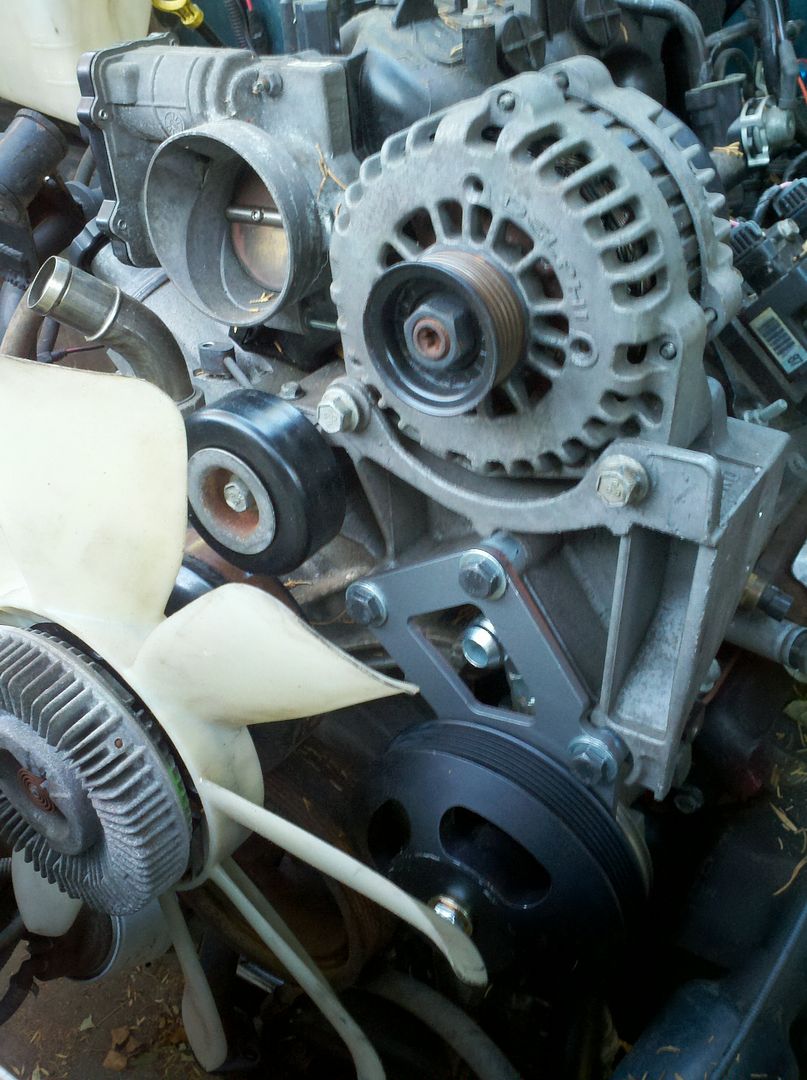

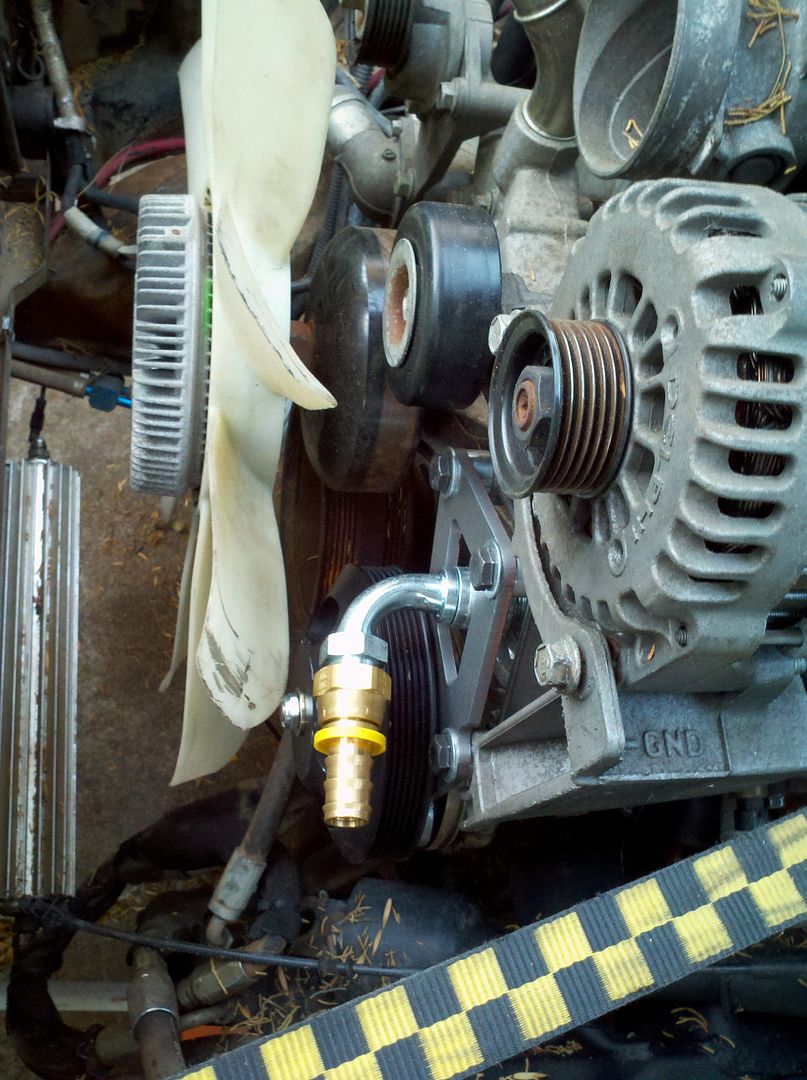

Kevin came out Sunday, mostly so his wife could go hang out in the pool with my significant other, but partially to give me a hand. He knocked out a cooler mount, modded the ECM mount for the early LS computer, got the relay block mocked up waiting on hardware and mocked up the factory'ish intake and helped me decide to just relocate the battery tray. Thanks buddy.

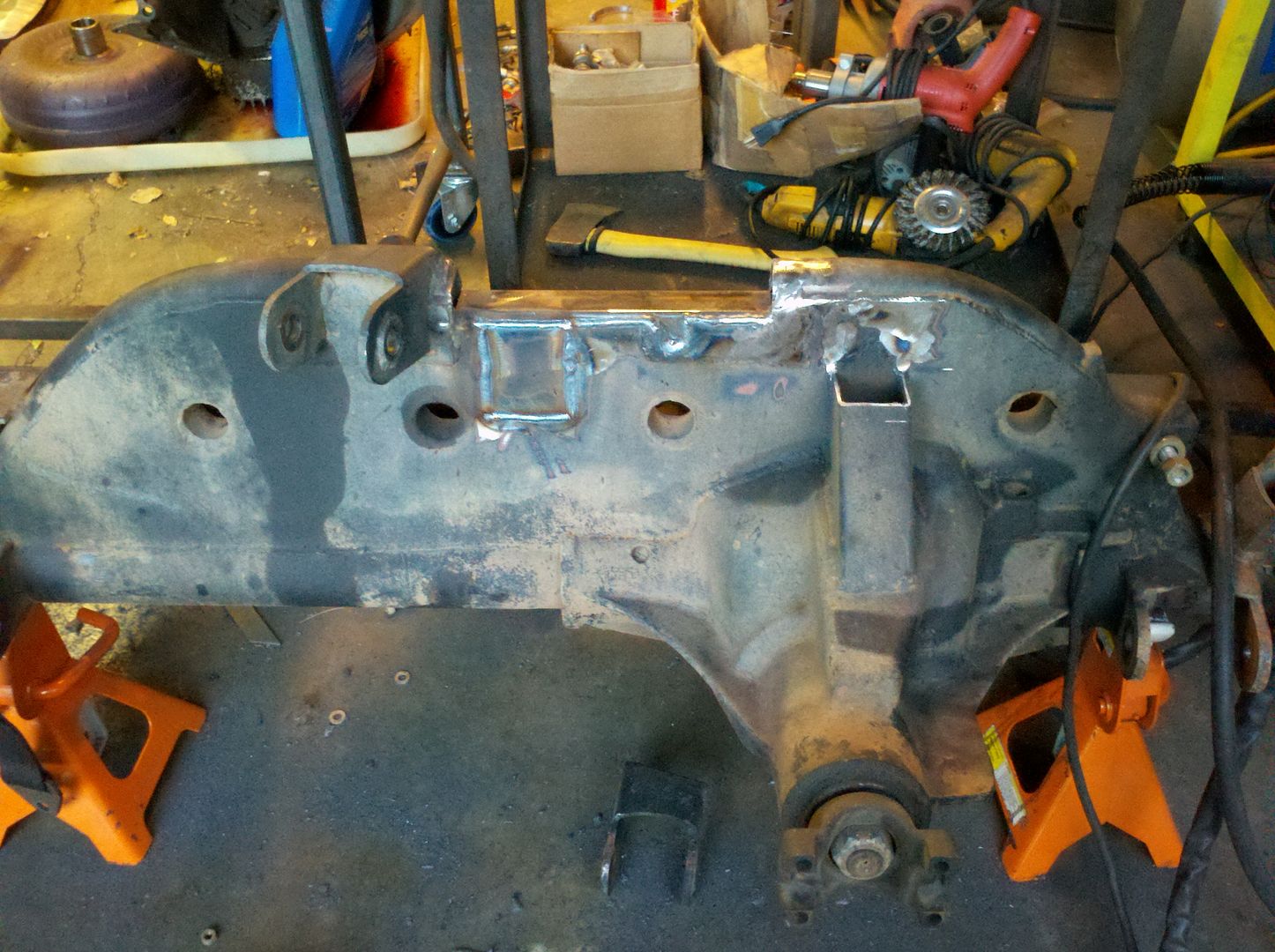

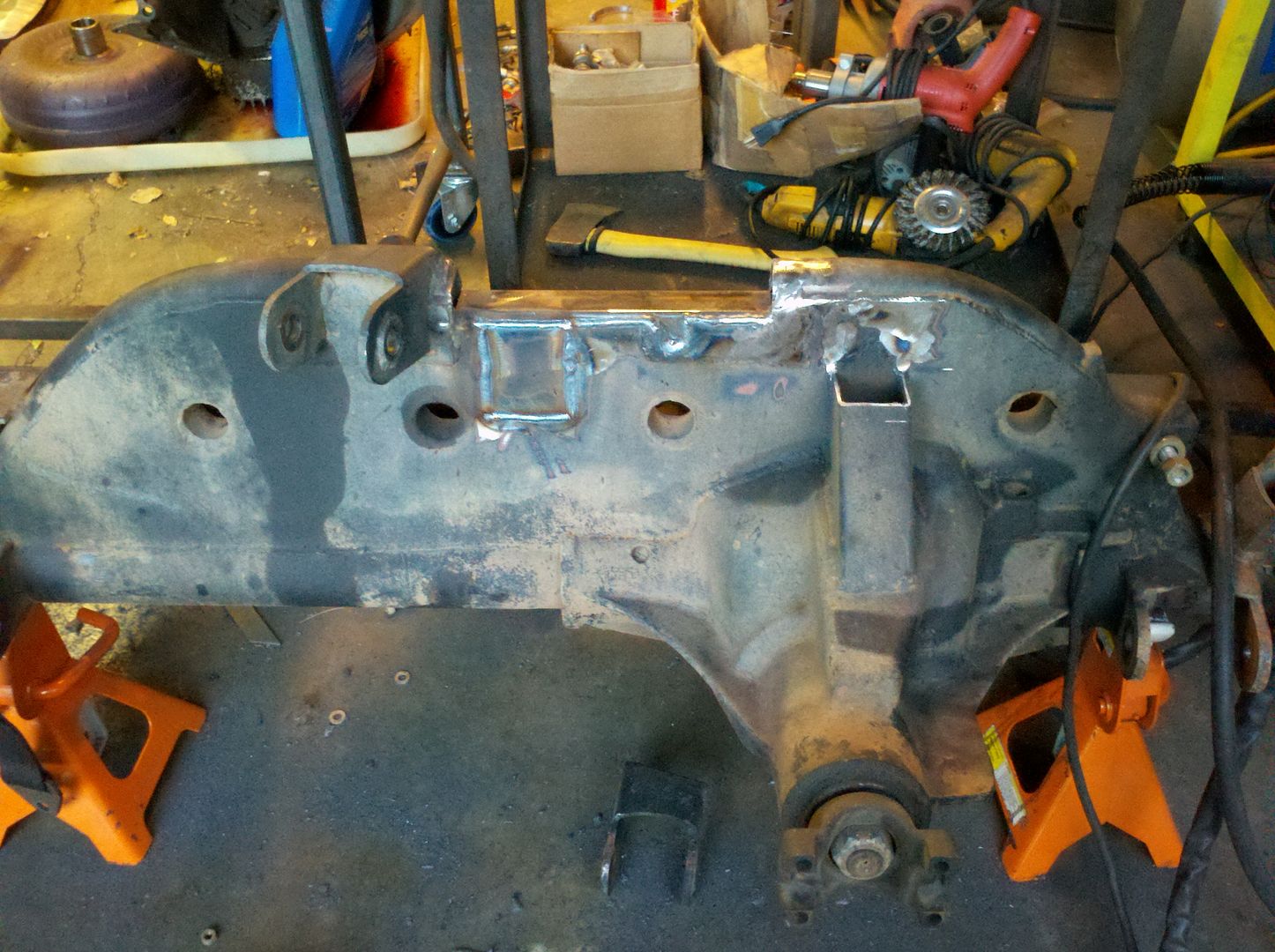

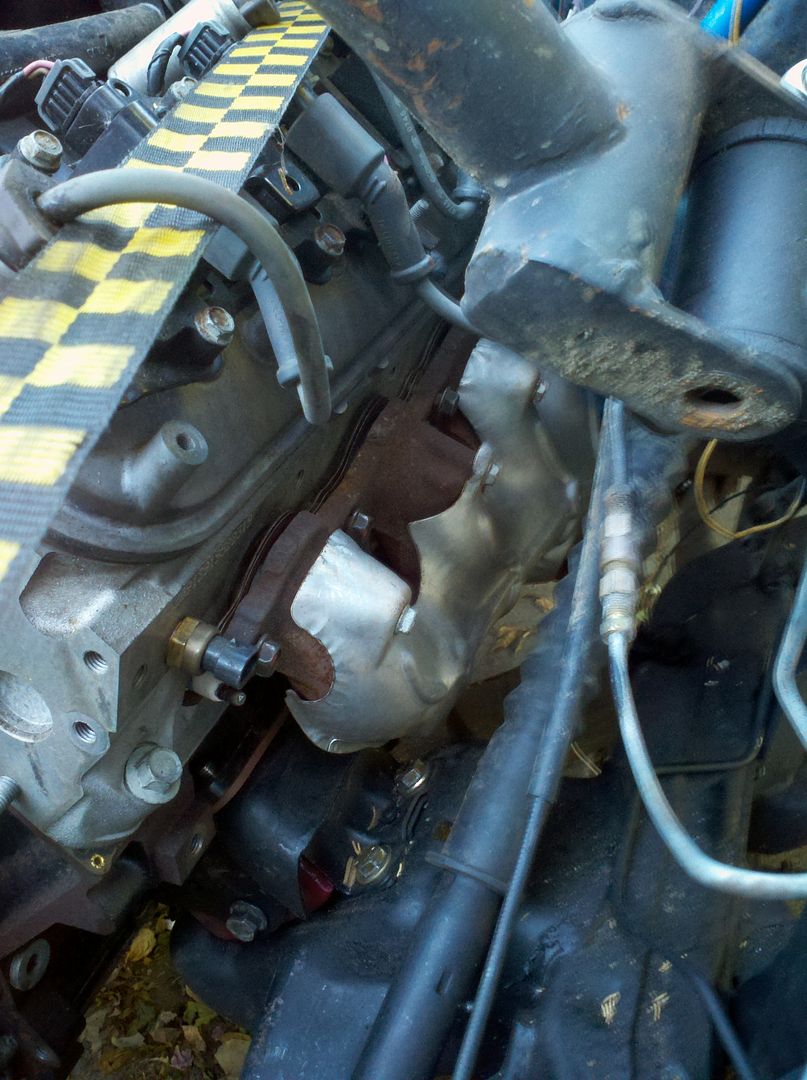

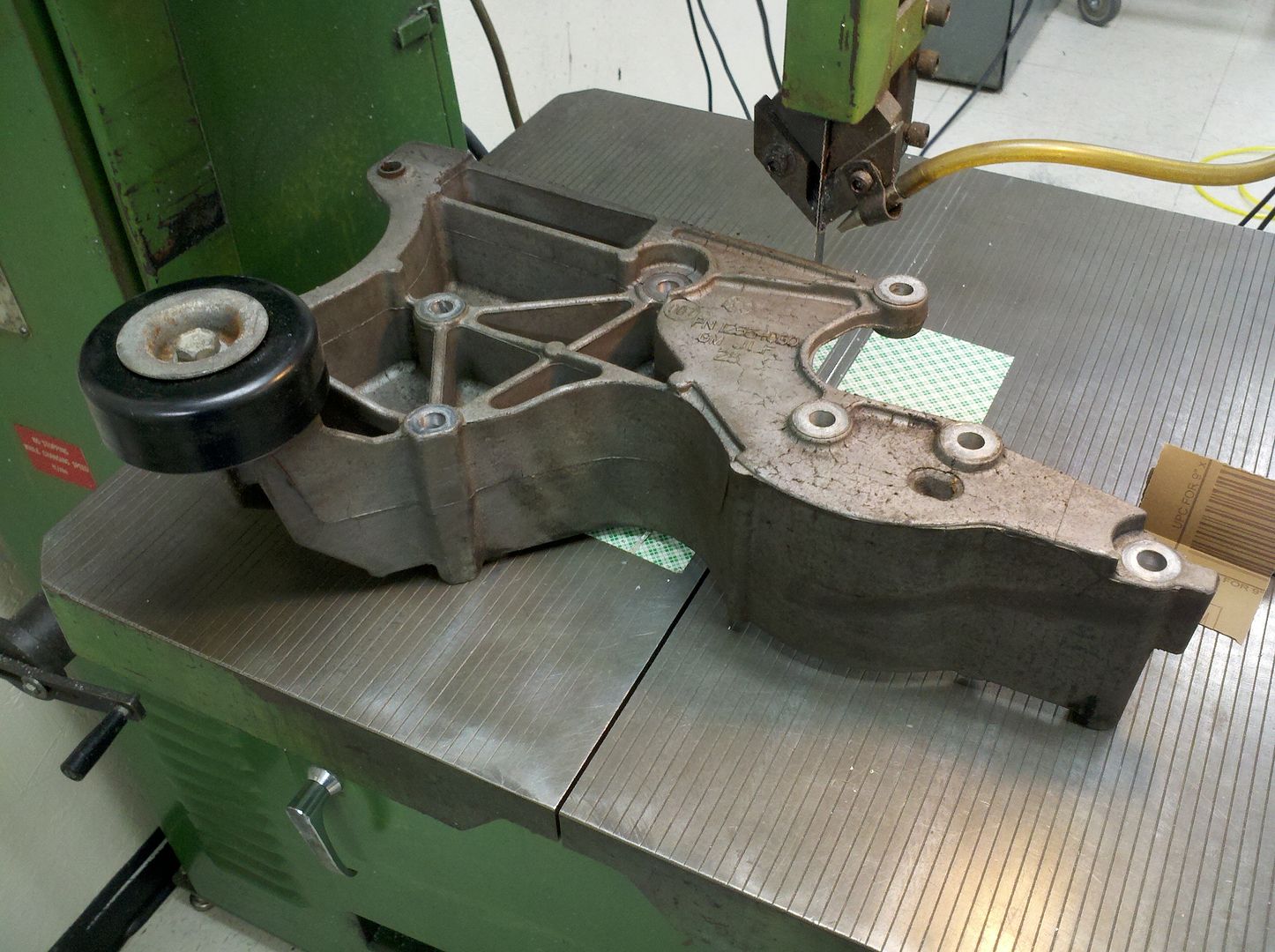

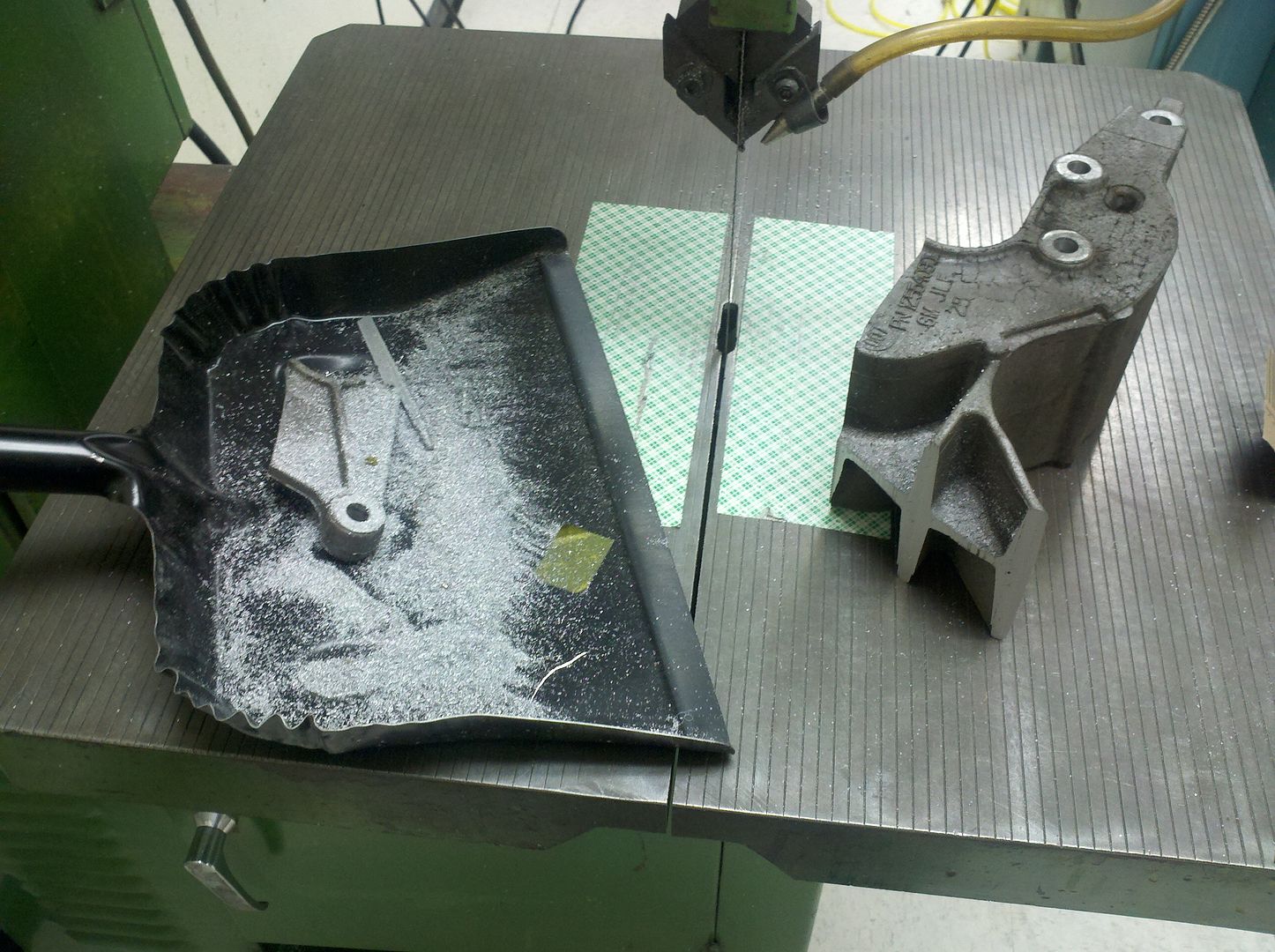

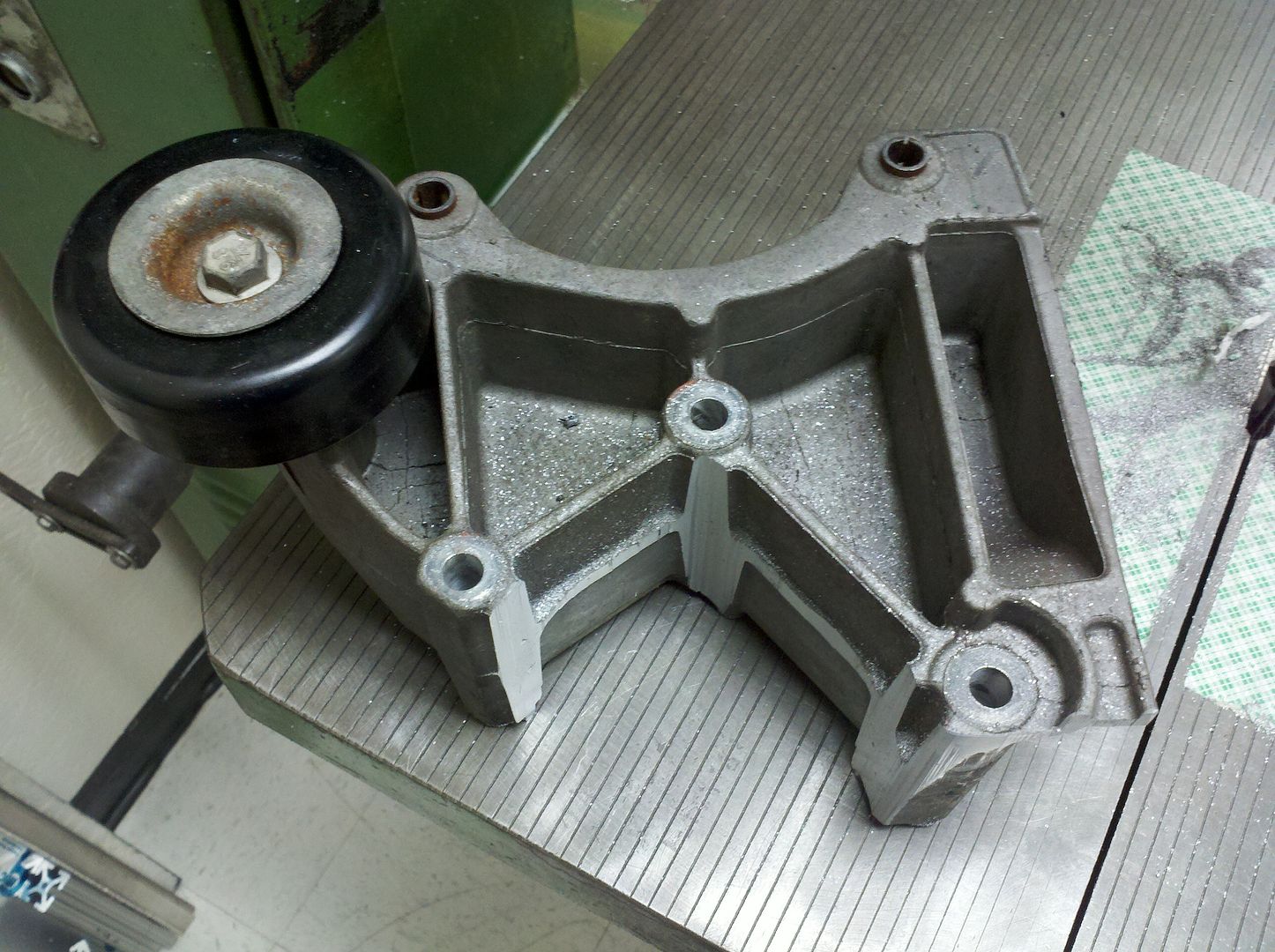

While he was doing that I was trying to fix the issues that the motor mount plates created. The t-case was hitting the back of the front 2x3 piece of tube and the ghetto mounting foot for the tranny adapter wasn't long enough.

I notched and plated in the relief for the t-case a well as removed the entirety of the ghetto mount.

I cut a piece of 1/8" laying around for a cover plate and integral shim, then made a C out of some 2x2 .120 and burned it all together and made my top side holes with counter bores on the back side for clearance.

Finished it off later last night after everybody had left by blazing it on. Now lets just hope my tape measure operating skills are up to par, eek.