Got a lot of updates, been slacking on here, but not on the truck.

Got all the rear frame finished up, fuel tank installed, brake line shortened, flared, and brakes bled, new pads and turned the rotors in the rear, bolted up the B&W gooseneck and 2" receiver hitch, and took it for a test drive, everything seems to work okay the little I drove it. Then bolted the bed on, and bought an 08 bumper for it. Hooked up the filler neck to the factory door in the bed with two sections of rubber fill neck hose and a 90* steel elbow

How I slotted the front cross member so the fuel tank would slide ahead far enough to clear the back of the frame, and added a new place for the brake line since it hit the tank skid plate then.

Once the back was complete, I started to tear down the front to remove the engine, getting to the really expensive part of this build now....

- - - - - - - - - -auto merged double post- - - - - - - - - -

Somewhere in between I cleared the headlights, and cut out my own clear reflectors since I don't like painted ones.

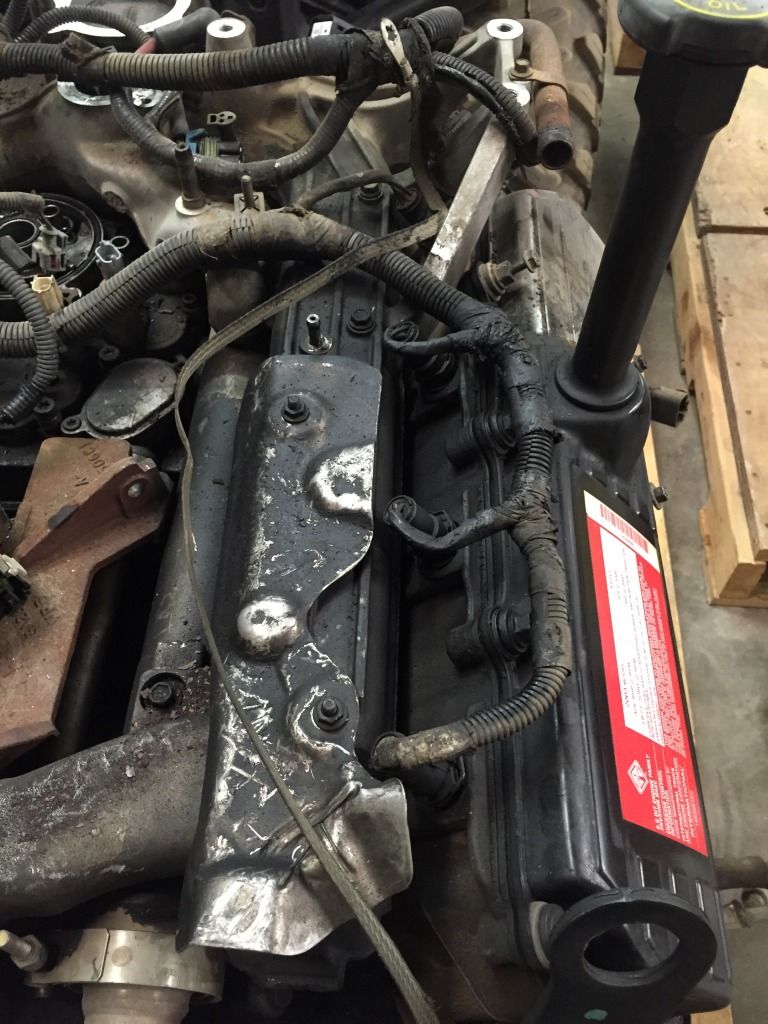

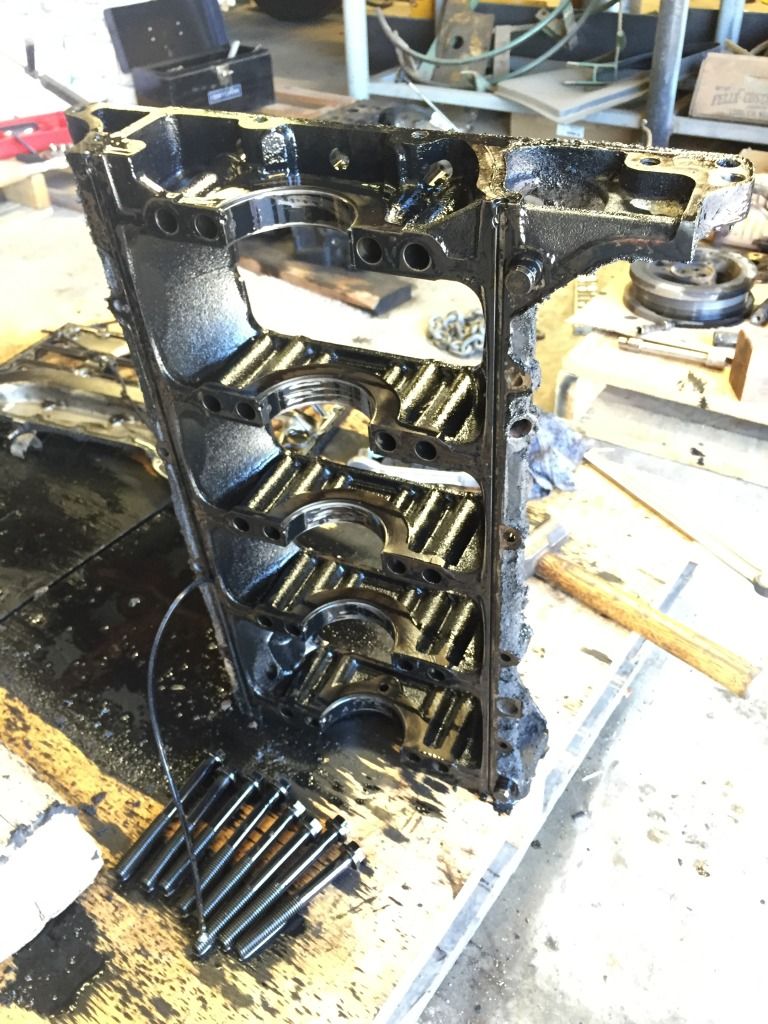

Onto the engine pics, this 6.0 lived up to the name six-leaker very well...

Entire side of the block, frame and oil pan was solid crusty and fresh oil.

Top of the engine valley, oil cooler and hpop cover were all coated in oil.

Engine pics

- - - - - - - - - -auto merged double post- - - - - - - - - -

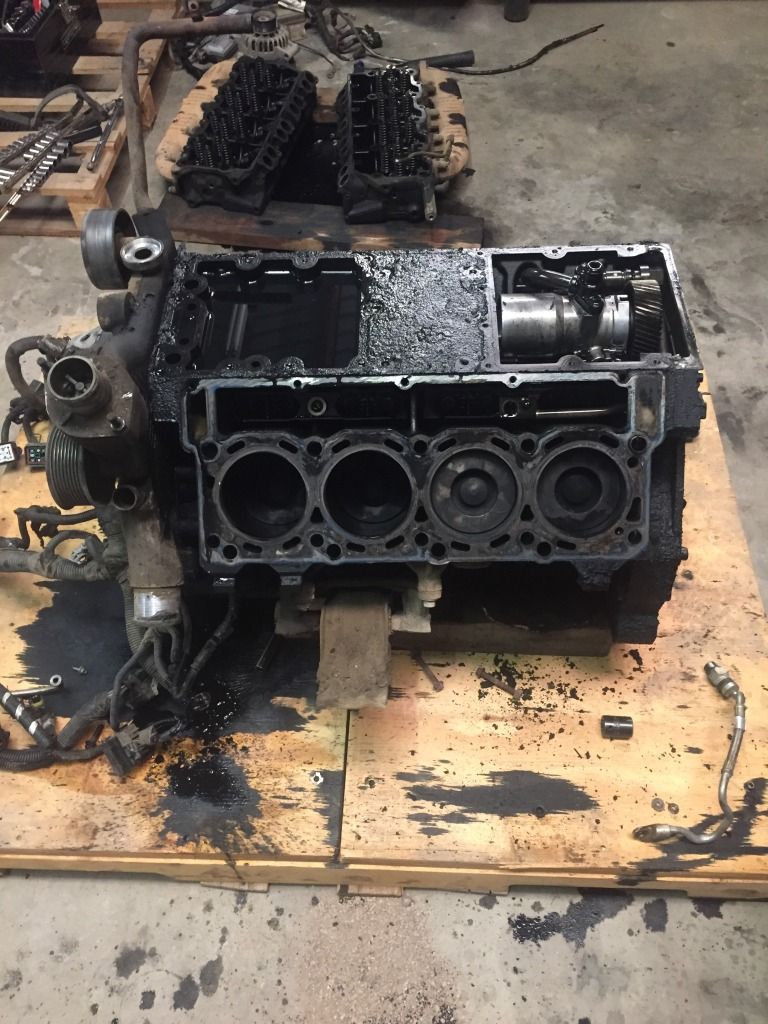

I disassembled all the engine myself, and I have never seen an engine as oily as this one. Safe to say a full rebuild and all new gaskets was in order if I ever wanted this thing to be right.

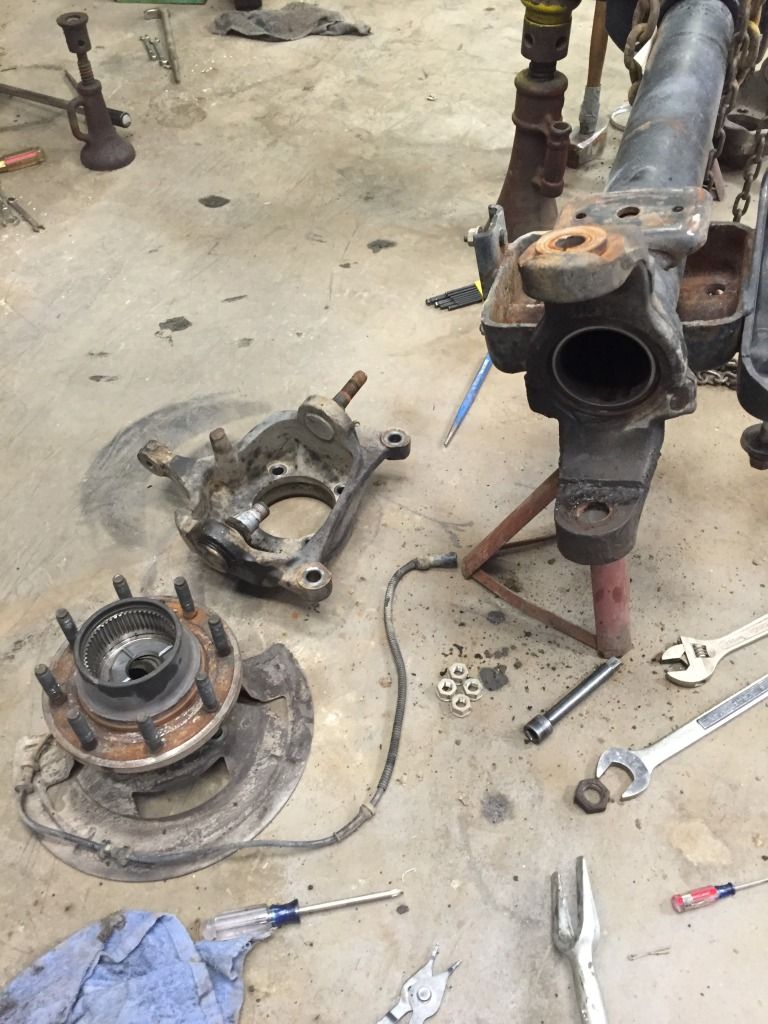

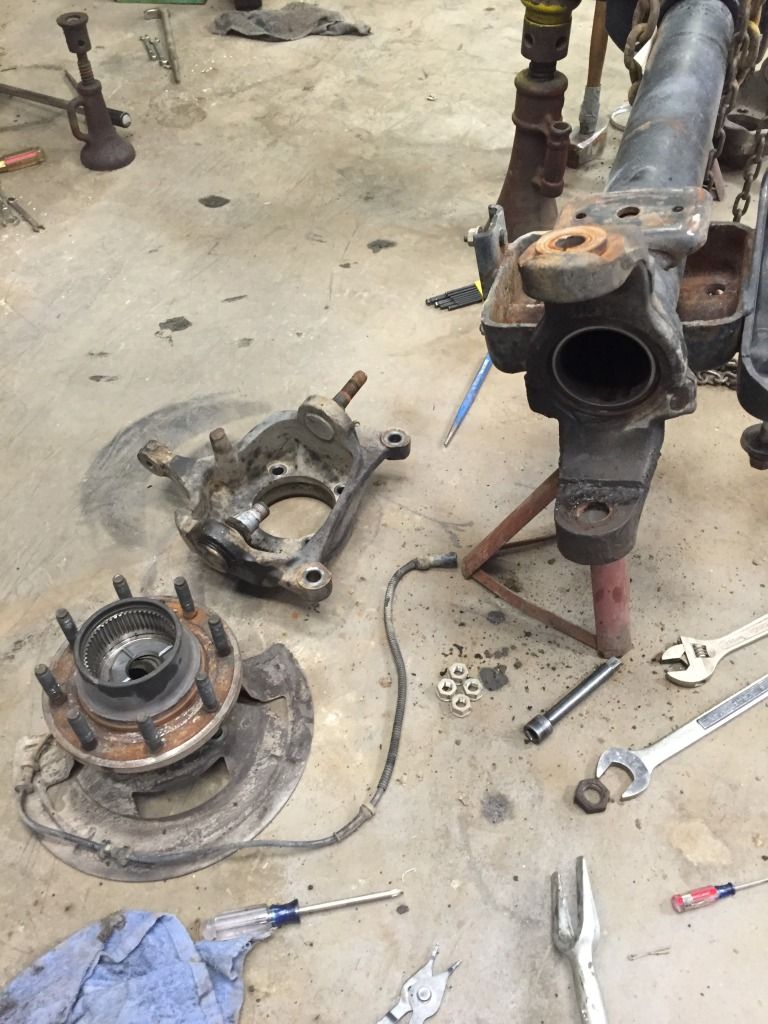

Also decided to clean up the engine bay, paint it all gloss black, and install the lift while it was easy to access. Pulled the axle out from under the truck, pulled the cover, resealed it and put in fresh oil, then changed the axle dust seals, hub seals, balljoints, and regreased everything in the hubs, reinstalled my warn locking hubs, and painted everything black again.

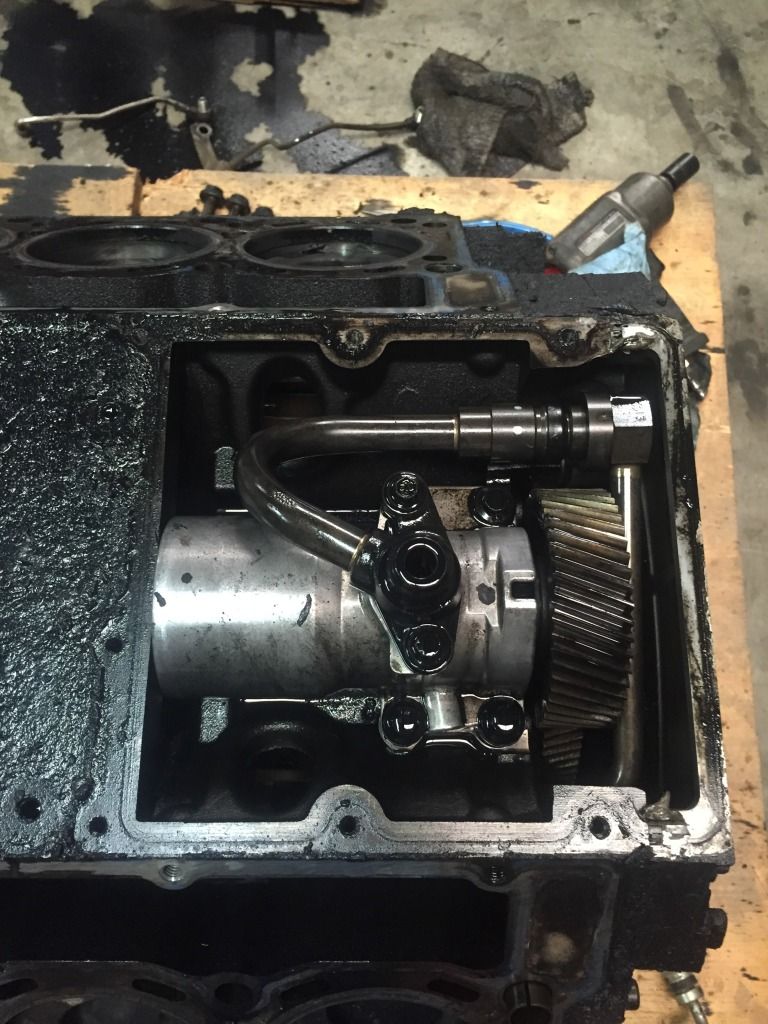

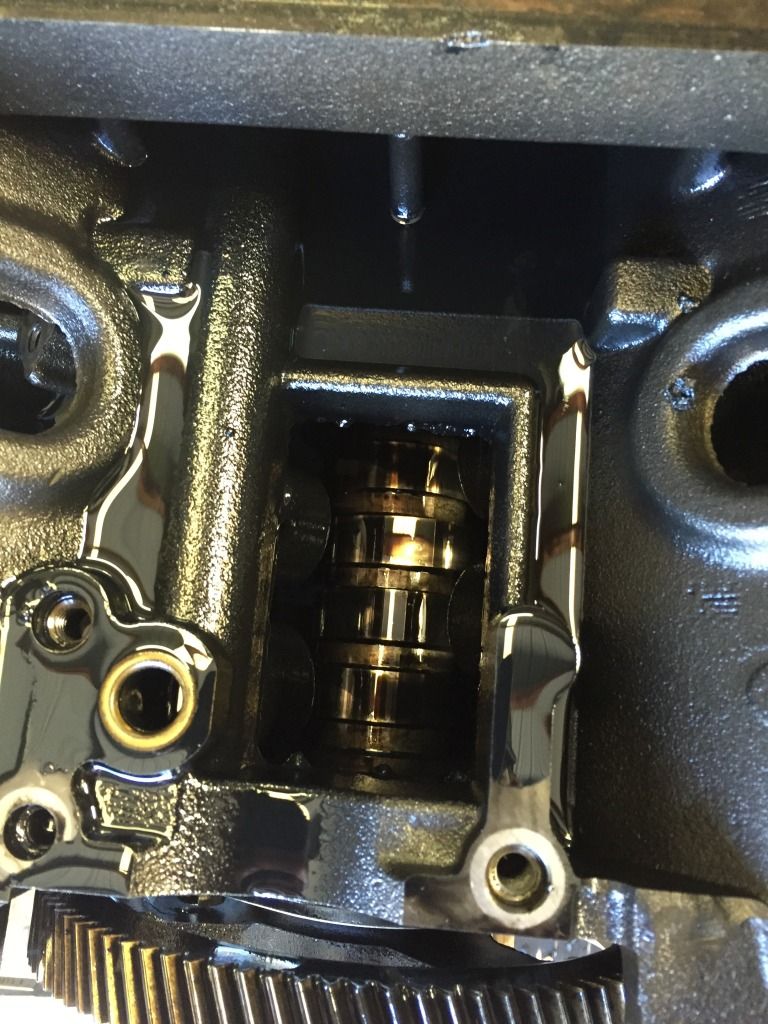

Now the latest news, I visited the machine shop that's doing the engine. He told me the bottom end all checks out fine, so he will be honing the cylinders, line hone the crank bearings, polish the crank, and put new rings on the original pistons, as well as new rod, main and cam bearings. Bad news, the heads were toast. Numerous cracks in the exhaust valve seats revealed by magnfluxing, some almost 3/4" long, all valve guides are worn, and the heads are warped. So we elected to order new heads rather than spend a ton trying to repair and rebuild the originals. I should have the engine back in 2-3 more weeks. I also installed new front fenders since these pictures were taken, and picked up a new driver's side door I will be hanging tomorrow. Then the truck will be ready for it's engine when that is done. Interior is complete too minus a new headliner.