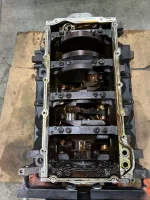

So as I pulled into the shop Sunday, I rolled past 498mi on the near rearend setup. So what did I decide to do? Start yanking the motor out  I've been planning this for a long time anyway, this 5.3 leaks from every orifice

I've been planning this for a long time anyway, this 5.3 leaks from every orifice

First thing's first, put the hood in service mode. Didn't know this was a thing till like 2 years ago, wish I would've known all these years with all these trucks lol. 'Course this is the first one I'm doing serious work on

Another goal of this job is to re-loom the harness cuz all the factory stuff is just brittle as hell and falling apart

This truck had a fresh trans put in it a couple years ago so thankfully the Y-pipe didn't fight me too bad other than this one nut. I'm gonna have to replace this one

The first real hiccup I ran into was the damn spark plug wires and plugs. Whoever did the tuneup before I got it didn't put a SINGLE DROP of antiseize or dielectric grease on these things so they were seized on there hard. Ended up pulling the front liners out to get better access

First thing's first, put the hood in service mode. Didn't know this was a thing till like 2 years ago, wish I would've known all these years with all these trucks lol. 'Course this is the first one I'm doing serious work on

Another goal of this job is to re-loom the harness cuz all the factory stuff is just brittle as hell and falling apart

This truck had a fresh trans put in it a couple years ago so thankfully the Y-pipe didn't fight me too bad other than this one nut. I'm gonna have to replace this one

The first real hiccup I ran into was the damn spark plug wires and plugs. Whoever did the tuneup before I got it didn't put a SINGLE DROP of antiseize or dielectric grease on these things so they were seized on there hard. Ended up pulling the front liners out to get better access

Last edited: